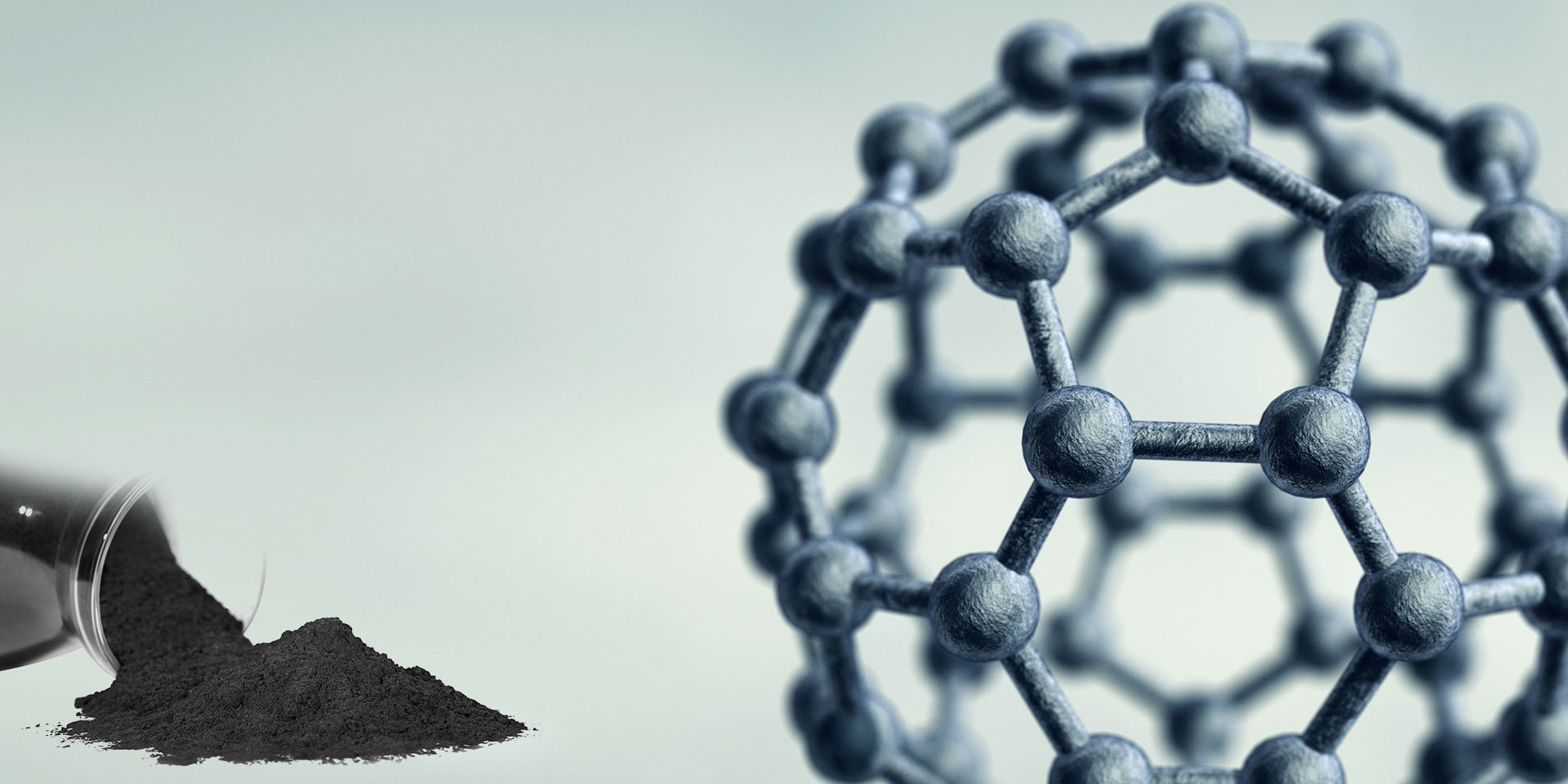

Application of flake graphite in the coatings industry

Release Date:

2020-03-27

Flake graphite As a functional filler in coatings, it is mainly used in anticorrosive coatings, fire-retardant coatings, and conductive coatings

As an anticorrosive material, the rust-inhibiting primer made from it, carbon black, talc powder, and oils has good resistance to chemicals and solvent corrosion. If chemical pigments such as zinc yellow are added to the formula, its rust prevention effect is even better

Expandable graphite is used as a fire-retardant filler. It is an intercalated graphite compound obtained from natural graphite flakes through chemical or electrochemical treatment. Under heated conditions, expandable graphite rapidly expands in volume (up to 300 times), suffocating the flame and simultaneously forming expanded material, thereby achieving the effect of isolating the flame, delaying or interrupting flame spread. Moreover, it is non-flammable, has good flexibility, high surface energy, and good char layer strength. However, the volume and dosage of the expanded material must be selected appropriately. Experiments show that particles of 150um, an expansion ratio of 30%, and a dosage of 5% are most suitable

Flake graphite It can be directly used as a carbon-based conductive filler, or it can be made into a composite conductive filler for conductive coatings. However, due to the large amount of graphite flakes added, the coating's performance becomes brittle, which limits its application. Therefore, measures should be taken to further improve the conductivity of graphite and effectively reduce the amount of graphite flakes added

Short-cut fiber material with good anti-deformation and cracking properties serves as a functional filler in solvent-free, thick-film conductive coatings. This coating offers resistance to corrosive media penetration, low residual curing stress, good resistance to substrate deformation and cracking, stable construction performance, and long-lasting static electricity dissipation. It can be used for antistatic coating on the inner walls of crude oil storage tanks. According to reports, applying metals such as copper, nickel, and silver to graphite powder using electroless plating technology to prepare composite conductive fillers, when used in conductive coatings at a 30% concentration, not only results in excellent conductivity but also further improves corrosion resistance

Previous Page:

More News

Qingdao Jinhui Graphite Co., Ltd.

Address: Nantanpo Village, Zhangshe Town, Pingdu City, Qingdao, Shandong Province, China

Fax: 0532-87389988

15253235217General Manager Wang,15263665989Manager Cao

Email:

jinhuishimo1999@sina.com

Product Series

Business inquiry

Note: Please leave your contact information, our professionals will contact you as soon as possible!

Copyright © 2022 Qingdao Jinhui Graphite Co., Ltd. All Rights Reserved

0532-86378899

0532-86378899

联系我们

联系我们