Purification method of high-carbon graphite powder

Release Date:

2020-09-24

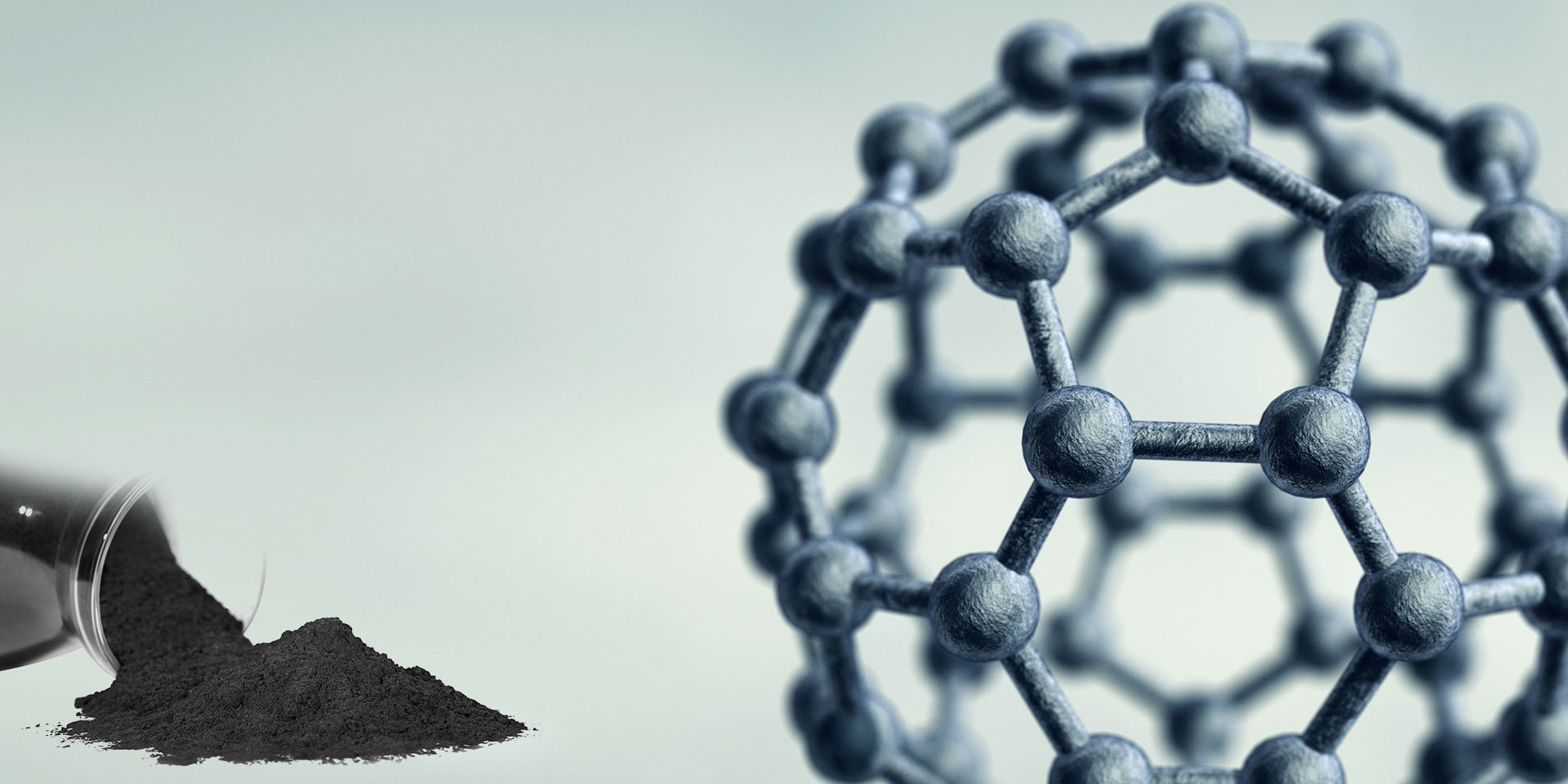

High-carbon graphite has high carbon content, carbon graphite, carbon graphite powder, carbon content is usually above 90%. There are many methods for carbon graphite purification. Carbon graphite powder purification methods can produce high-purity graphite powder with carbon content greater than 99.9%. We have summarized various purification methods and high-purity graphite powder technologies.

High-carbon graphite Powder purification methods are divided into two main categories: chemical purification and high-temperature purification. Chemical analysis purification problems include both acid method and alkali-acid method. Let's briefly introduce and study these three high-purity graphite powder purification methods:

The process is now a feasible and mature method for contrast purification. The purification method for high-carbon graphite powder is basically acid purification by technicians: add graphite material, various acids, react in a reactor to remove impurities, wash, dehydrate with a centrifuge, discharge, dry, and treat wastewater徑。

Alkali-acid method The caustic soda method involves calcining impurities in graphite with caustic soda at high temperatures to produce soluble active silicates and hydroxides. After desilication by washing with water, other impurities react with hydrochloric acid to produce water-soluble chlorides, which are then washed away. The process involves main ingredients, stirring, high-temperature partial melting, leaching during cooling, washing, dehydration, and drying徑。

High-temperature purification method uses graphite's high-temperature resistance. When heated to a certain degree, impurities will evaporate as gas. Graphite's boiling point is greater than 3700 degrees Celsius. This method has high energy consumption and high cost. It is difficult to achieve industrial large-scale production, except for some military or special applications径。 High-carbon graphite powder purification methods, the purification method for high-carbon graphite powder is the first of these methods. Graphite powder manufacturers will use different purification technologies based on their skills and equipment. 。

Previous Page:

Next Page:

More News

Qingdao Jinhui Graphite Co., Ltd.

Address: Nantanpo Village, Zhangshe Town, Pingdu City, Qingdao, Shandong Province, China

Fax: 0532-87389988

15253235217General Manager Wang,15263665989Manager Cao

Email:

jinhuishimo1999@sina.com

Product Series

Business inquiry

Note: Please leave your contact information, our professionals will contact you as soon as possible!

Copyright © 2022 Qingdao Jinhui Graphite Co., Ltd. All Rights Reserved

0532-86378899

0532-86378899

联系我们

联系我们